|

|

|

|

|

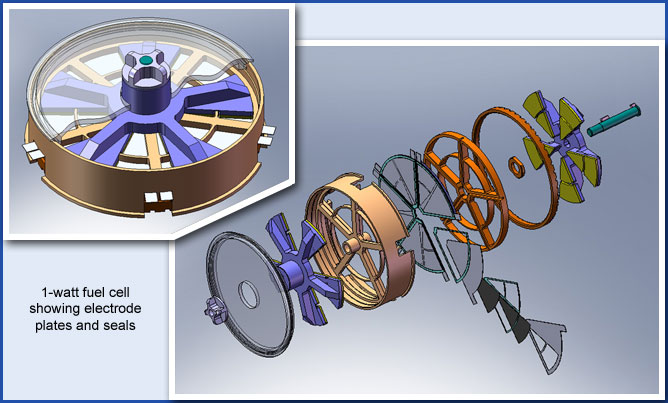

DIRECT METHANOL

FUEL CELL CHARGER PROTOTYPE

University of British Columbia, Clean Energy Research Centre

This 1-watt fuel

cell utilizes variable exposed plate geometry to control power

output for charging personal electronic devices.

- Developed a system of

seals between the stack of plates to facilitate sealing in

conjunction with variable geometry

- Optimized effective

plate area to minimize overall size of the unit

- Designed using

SolidWorks

|

|

|

FUEL PUMP for TRUCK HEATER

Teleflex

Canada Ltd.

These

diesel-fired, microprocessor-controlled truck heaters are used to

heat the engine and cab of highway trucks or busses. The

competitor’s product has both supply and return hoses for the fuel,

requiring two connections into the vehicle’s fuel tank.

- Developed a method of automatically

purging air out of the fuel system, eliminating the need for a

fuel return line. The system met the requirements and surpassed

all performance expectations. It gave Teleflex a decided

advantage over the competition.

|

|

|

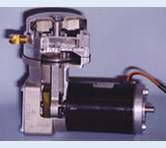

AIR COMPRESSOR for US ARMY FIELD COOK STOVES

Teleflex Canada Ltd.

Teleflex developed new cook stoves for the US Army to replace

the aging units previously in use. The new stoves were developed

to meet their single fuel mandate. The stoves burn jet fuel,

which is also used in the Army’s tanks, aircraft and trucks. The

burner units fit various appliances, for grilling, baking, etc.,

and are automated with such features as push button start, stop,

and refueling.

- Developed a small modular air compressor

to be used in the Army stove and with some different internals,

in the company’s line of truck heaters. The compressor utilizes

some die cast and injection molded parts.

- The compressor is 10% more efficient

than the previous design, a key feature in a product where low

power consumption is a major selling feature. It is also 4

decibels quieter than its predecessor.

|

|

|

|

ROBOTIC WORKSTATION

National Research Council

A

computer workstation was developed that would allow a quadriplegic

to work in an office. File folders are stored in slots at the side

and back of the desk where a robot can access them. The robot

removes a folder from one of the slots and places it on an easel in

front of the disabled office worker. Using voice commands, the

documents can be retyped, printed, stamped and filed for mailing

etc.

Designed manufactured and tested the mechanical parts of the system:

- Custom-designed workstation with track

mounted robot

- Easel that opens file folders and

mechanical fingers that hold them in place

- Suction-operated page turning device

- Robot-friendly file storage racks

|

|

|

AIR SYSTEM for FUEL CELL BUS

Ballard Power Systems Inc.

These “clean air” buses for the cities of Vancouver and Chicago

are powered by fuel cells. The fuel cell engine consumes large

amounts of air which is supplied by a sixty horsepower

supercharger and a turbocharger.

- Designed the arrangement of the air

system to be shoehorned into a tight space between the fuel

cells and other engine components

- Modular design so the various parts

can be serviced easily, or removed as a unit for major repairs

|

|

|

ELECTROLYTE MIXING SYSTEM

Ballard Batteries Inc.

Ballard Batteries developed high energy lithium, sulfur-dioxide

batteries and required a mixing system for the electrolyte.

- Designed an apparatus to inject lithium

bromide powder while excluding air and maintaining an inert

atmosphere within the system

- Reduced production time for batteries by

two technician-hours per day

- The cost to design, build and install the

apparatus was 75% less than the alternate method

|

|

|

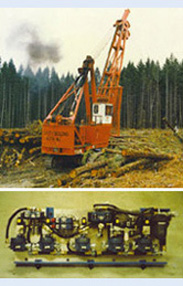

PNEUMATIC CONTROL SYSTEM for GRAPPLE YARDER

RSI Research Ltd.

Hundred-ton grapple yarders are used to haul felled trees out of

a logged area to where they can be loaded onto logging trucks.

Older machines required a high skill level to operate; having

numerous levers and foot pedals to control the various cables,

open and close the grapple as well as swing and travel. RSI

developed a single joystick to control all functions except

travel.

- Designed a proportional pneumatic system

to control clutches and brakes for the cable winches.

- System was designed to override the

older, manual valves but could be bypassed to operate the

machine manually if required.

|

|